Rename, cancel, delete layout jobs

Quilter's home page and candidate reviewer got a small design refresh that makes it easier to browse and organize your layout jobs.

On our Home Page, you've now got the ability to:

- Search and sort layout jobs using their name or submission status

- Rename or delete draft and completed jobs that you need access to anymore

- Cancel submitted jobs that are misconfigured or contain errors

On our Candidate Review page, we've streamlined the job details header and moved information about your input files to a "Details" modal accessible from page header.

Bypass Capacitors

We’re pleased to announce a small but mighty EDA industry first:

Quilter can now automatically detect, associate, and place bypass capacitors in new layout jobs, validating every placement decision using our new Physics Rule Checks framework.

Here's how it works:

1/ Quilter automatically finds bypass caps

After uploading your input files, Quilter automatically detects bypass capacitors and determines which components and pins need decoupling.

2/ Submit your layout job

Quilter optimizes placement for all identified bypass caps. Even in this first release, our algorithm will:

- Strategically place smaller capacitors near high-current voltage sinks to minimize impedance and stabilize power delivery, preventing voltage drops.

- Identify and optimize 1:many bypass capacitor relationships between ICs and their capacitor banks to ensure distributed decoupling across frequencies.

- Minimize overall power delivery impedance by reducing trace length and via count, lowering parasitic effects in the decoupling network.

3/ Review layouts and physics rule checks

Each candidate layout includes Physics Rule Checks (PRCs) for every bypass capacitor, verifying proper placement near assigned pins and minimal via usage.

Physics Rule Checks

We're pleased to announce the launch of Physics Rule Checks (PRCs) in Quilter, which work alongside existing Design Rule Checks (DRCs) to ensure Quilter layouts:

- are complete,

- are manufacturable, and

- function as specified.

Physics Rule Checks are fully automated “unit tests” that Quilter creates for each physics constraint defined in your schematic.

After generating a layout, Quilter runs a targeted suite of PRCs to quantify the design quality of each candidate, and packages these results into a report for you to review.

When viewed alongside DRCs, physics rule checks make it easier to explore and understand design tradeoffs between manufacturability, cost, and performance so you can optimize for what’s most important to you.

We'll soon be integrating PRCs more deeply into Quilter’s candidate review experience, including using PRC results to drive candidate recommendations, filtering options, and enhanced visual review workflows.

We're excited to hear what you think!

🏎️ Quilter's router is now 7x faster

Our new local routing module reduces routing time by 7x, overall job time by 3.5x, and improves success rate for complex boards

Before publishing updates to our AI design engine, we first complete a standardized benchmarking process. This process – which we call ”Qtest” – ensures all changes we make push system performance up and to the right.

Qtest is composed of a suite of internal test boards that fully exercise Quilter’s capabilities against a wide range of design scenarios. For our benchmark to complete successfully, all boards in the test suite must meet or exceed previous benchmarks for:

- completion %: did we finish the design?

- manufacturability: did we design it with more conservative tolerances? (ex: trace widths)

- job duration: did we design it faster than before?

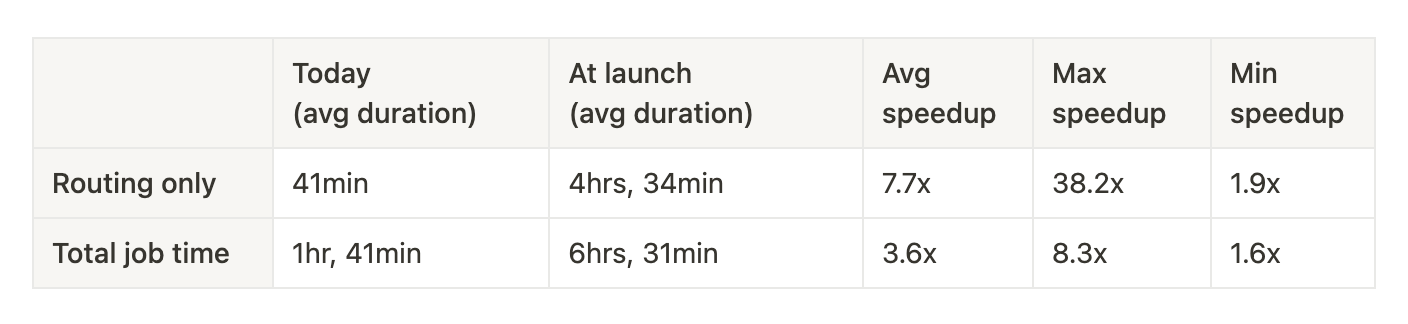

Here’s a simplified summary of results from our latest benchmark, compared against performance at the time of our Open Beta launch in mid-February:

This benchmark shows significant improvements across routing efficiency and, as a secondary benefit, total job time:

- Routing got 7.7x faster, from an average of ~4.5hrs to 41 mins, with a maximum improvement of more than 38x 🤯

- Overall jobs got 3.6x faster, from an average of ~6.5hrs to 1hr 41 mins, with a maximum improvement of 8.3x 🚀

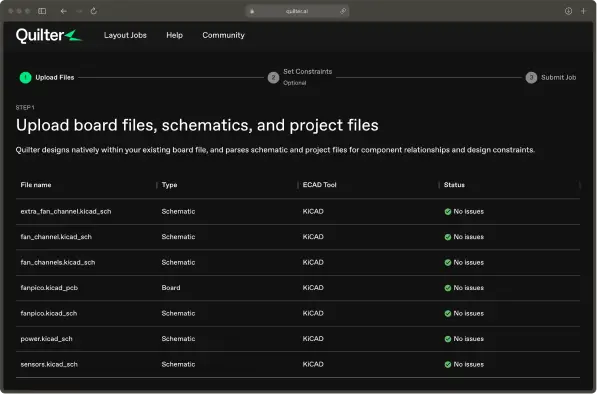

A brand new Quilter app

We've entirely rebuilt Quilter's web app to improve our job creation, submission, and review workflow.

We've entirely rebuilt Quilter's web app with a focus on "reliability" – our ability to consistently set and deliver on our users' expectations for the job they submitted.

1/ Proactively resolve job configuration issues

In the new app, we've significantly improved the clarity and rigor of our submission workflow to:

- Surface clearer and more actionable upload errors for input files

- Visually preview your board file before submission to better identify board or component-level parsing issues

-

Check for common job configuration issues so they can be resolved prior to submission

(ex: "You've uploaded a fully routed board – there's nothing for us to do.")

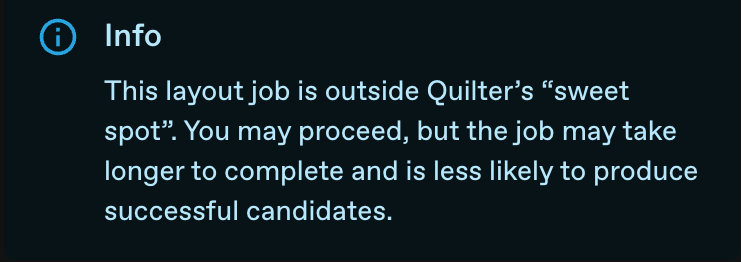

2/ Set clearer expectations for your job

In the new app, we've created a much more clearly defined "happy path" that provides tips and information along the way to ensure you get our best results for each job you submit.

The app will also do a better job of keeping you informed as its capabilities improve, so it's always clear over time which jobs you can trust Quilter to tackle.

3/ Provide better transparency into jobs and candidates

Because Quilter jobs currently take tens of minutes to hours to produce its first successful candidate, we've invested significantly in improving clarity and transparency into the status of Quilter jobs and design candidates.

In the new app, you'll see significant changes to:

-

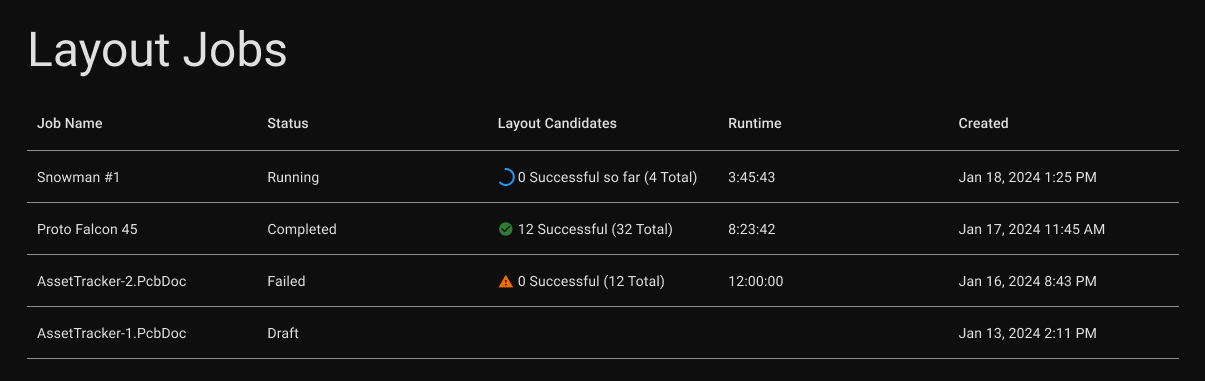

Layout jobs summary

On the new job summary page, you'll get much more granular visibility into the status of each job you've submitted – its runtime, and the number of total and successful candidates that each job has produced.

-

Layout job details

Every job details includes a clear summary of its current status as well as all the input configurations that you set when you submitted the job, making it easy to tweak and re-run design jobs.

-

Candidate details

We've rebuild the candidate viewer to ensure that we're more effectively focusing your attention on the best candidates, and created new global candidate filters to help you quickly narrow your solution space with custom requirements.

Community forums

Quilter's forums are a place to share, learn, and engage with the Quilter team.

We're excited to announce the launch of Quilter's community forums, a new space for Quilter users to:

- Ask questions and get helpful tips on using Quilter

- Post Quilter-designed projects and share feedback with the Quilter team

- Submit, view, and vote on suggested improvements to Quilter's product

- Stay up-to-date on Quilter news and product updates

If you're interested in learning more about how Quilter works today or where it's headed in the future, our new community forums are the place to be.

To join the community, simply head to https://community.quilter.ai and log in using your existing Quilter account.

We'll see you there!

Thin-to-thick traces

Quilter's design agent can now route thin-to-thick traces to support designs with fine-pitch ICs.

Quilter's "constraints manager" allows users to identify minimum amperage or trace width requirements for sensitive nets and pins so that Quilter's design agent can route those paths using beefier traces.

What happens, though, when the need for a beefy trace meets a delicate, finely-pitched connector or IC?

Previously, the answer was that Quilter failed to route your design to 100%, leaving you to finish the job it should have completed on its own.

Starting today, the new answer is: success!

As of today, Quilter's design agent can now selectively route "thin-to-thick" traces just like a human designer would, enabling it to complete layout jobs more consistently while obeying all user-defined design rules and constraints.

Octilinear trace routing

Quilter now utilizes octilinear trace routing for all generic traces routed by our design agent.

Early in our closed beta, we started asking users how they felt about the visual aesthetics of Quilter designs. Here's what they told us:

- "Aesthetically, these traces look very different than my layout, and my client may not like this."

- "It just strikes me as looking messier, you know? Like just kind of how the lines go all over isn't pleasing to my eye."

- "It would be nice if there was an option to use isotropic routing style or the orthogonal routing style."

You asked, and we listened!

Quilter now utilizes octilinear trace routing (45 and 135 deg angles) for all generic traces routed by our design agent.

While it's generally a myth that curvy traces are more "manufacturable" than octilinear ones, it's hard to argue that they don't look nicer and perhaps a bit more...human?

Have other ideas for how we could improve our circuit board designs? Let us know by sharing and voting on suggestions in the "Ideas" category of our community forums.

Quilter v0.5.0 release

We're excited to announce a number of improvements in our first officially versioned release.

Quilter Design Agent

- (New) Placement algorithm has been updated to our stable reinforcement learning placer

- (New) Schematic-informed placement for Altium designs

- (Improved) Better silkscreen placement (fewer collisions, placed closer to components) for KiCAD

- (Improved) More direct routing paths between connected components

Quilter App

- (New) "Feedback" widget for submitting bugs, feature requests, and design reviews

- (New) Help Center with documentation for submitting boards for layout

- (Improved) Ability to sort/filter successful candidates by multiple criteria

- (Fixed) Corrupted pours in exported design files (KiCAD)

- (Fixed) Failure to successfully parse boards some board files with drill holes (KiCAD)

- (Fixed) Failure to successfully parse some Altium schematics

Share ideas for our next feature, improvement, or bug fix with the Quilter team, here.

Constraints manager

A new way for Quilter users to define and manage design constraints.

We’ve launched Constraints Manager, a brand new way for Quilter users to define and manage trace width or amperage constraints for individual net classes, nets, or pins in their design.

Defining constraints ensures Quilter’s AI router will use trace widths that are appropriate for the physical and electrical constraints of the design.

After uploading your board, you can choose to define constraints (in amps or mm/mils), import constraints from a prior design, or continue without defining constraints.

Constraints manager is available today for all designs (KiCAD, Altium, EAGLE).